KBB ITALIA overhauls and upgrades used machinery and plants, with the aim of improving their potential, increasing their efficiency and reliability and reducing their running costs.

Systems and machines, overhauled and tested, can be installed or relocated at the customer's premises.

Revamping allows the life cycle of machinery to be extended by replacing or updating its technological system with modern, state-of-the-art solutions to increase machine productivity, reduce production costs and increase staff safety.

LINE

Do you need to increase your production?

We have a used line ready to use.

An excellent quality-price ratio to expand production without large investments.

Suitable for glass, PET, and formats from 0.5 lt to 1L.

Glass, PET

APPLICATION: Glass, PET

DOWNLOAD

TECHNICAL FEATURES

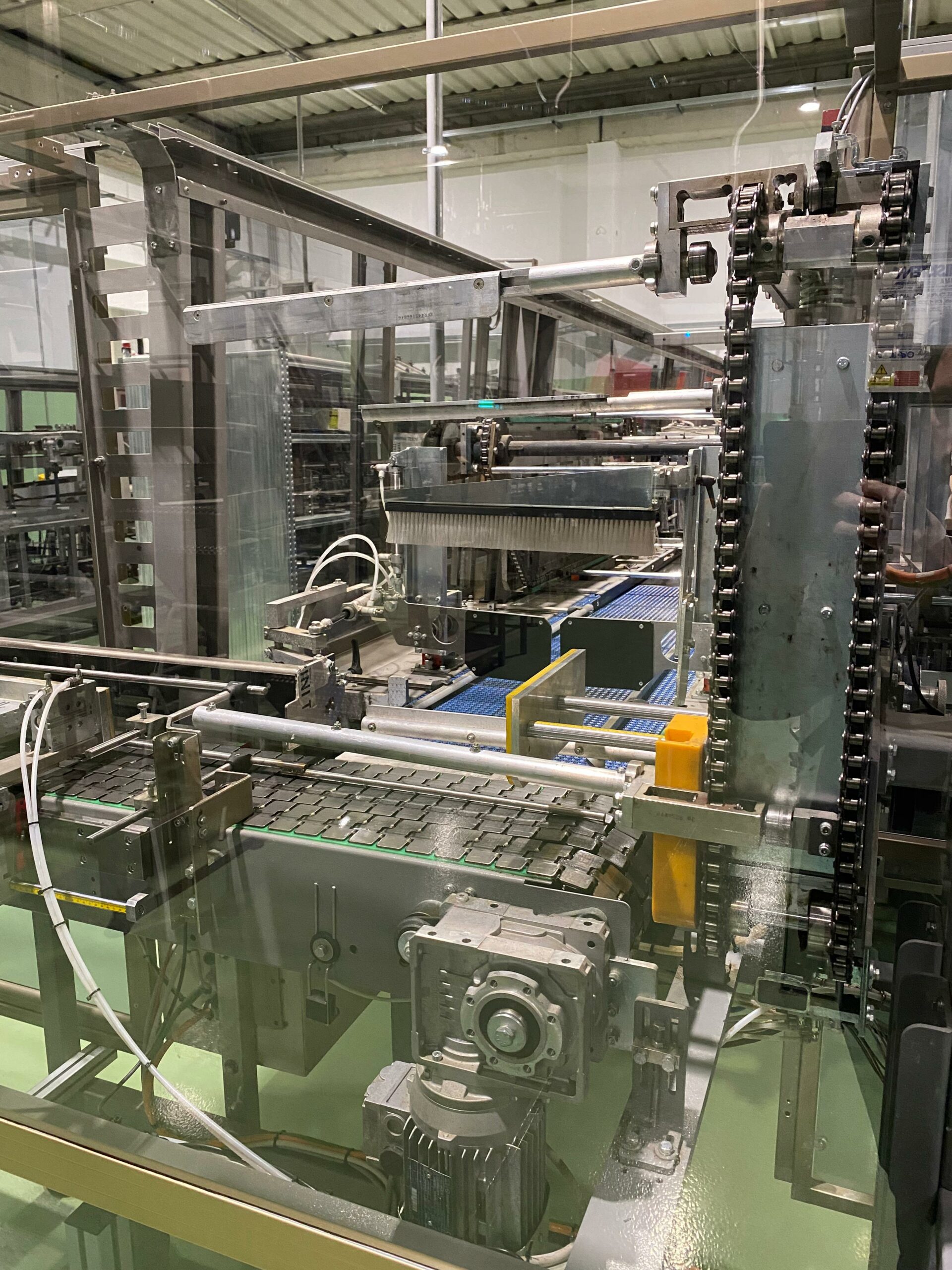

COMPLETE LINE WITH:

PACK LAB Linear Labeler

ATLANTA 90° infeed Shink Packer

ATLANTA inline infeed Shink Packer

DEPALLETIZER

Brand: CFT

Model: DA6

Year: 2008

Speed: 160 layers/h

Complete with:

- Perimeter protections with access doors

- Photoelectric barriers

- Transport pallets

- Platform for film removal

- Product unthreading bench

- Column for removing layers

- Lap warehouse

- Warehouse pallets

- Independent operator panel

- Electrical panel

LABELLER

Brand: PACK LAB

Year: 2008

Specifications: Linear

Label: n° 3 self-adhesive stations

SHRINK PACKER

Brand: ATLANTA

Model: COMBI GIOTTO 90-M

Year: 2008

Specifications: Automatic in-line

Carton packer: Wrap-around and tray

Bundling machine: Shrink film with film launch

SHRINK PACKER

Brand: ATLANTA

Model: COMBI GIOTTO 90-M

Year: 2008

Specifications: Automatic 90° entry

Carton packer: Wrap-around and tray

Bundling machine: Shrink film with film launch

| Applicazioni |

Glass, Pet, Taniche |

|---|---|

| Settore |

Oil |

| Marchio |

KBB Italia |

Technical

Expertise

Qualified

Assistance